Optimizing SMD LED and Optopipe® Light Pipe Integration

Comparing AlInGaP, GaP, and InGaN LED Technologies

Things to Know - SMT vs THT

Choosing LED Viewing Angles

Topics

At first glance, one may think that a light pipe is nothing more than a simple and easily produced molded piece of clear plastic. However, the reality is a bit more complex. Light pipes are precision-engineered optical components, like lenses and fiber optics, that guide light from the LED to the desired location on the outside of a panel or housing. They play a critical role in many of today’s HMI applications and require a high degree of reliability and performance.

Engineered for optimal light transmission

Light pipes use the principles of total internal reflection to control and guide light waves from the LED light source to the user interface. Their shape, with carefully designed angles, curves, and polished surfaces, guarantees minimal light loss throughout the body of the light pipe and maximum brightness at its endpoint.

High-End Materials

Instead of ordinary plastic, which is prone to yellowing, distortion, and other environmental stresses, light pipes are made from optical-grade materials, like polycarbonate. These materials are typically chosen for their high clarity, low absorption and are engineered to handle heat and harsh environments, making them ideal for optical components, such as light pipes.

Precision Manufacturing

Light pipes are molded and produced with exact surface finishes, polished or “frosted”, to control light transmission, reflection, and viewing angles. While most light pipes are designed to work with specific LED packages, certain light pipes are manufactured with light shields or housings made of rigid opaque materials to prevent light bleed or optical crosstalk between adjacent light pipes, allowing the use of several different LED configurations. Light pipes typically feature mounting pins or crush ribs for installation on PCBs or in panels that hold the light pipe securely in place during vibration.

Consistent and Reliable

Unlike “just a piece of clear plastic”, light pipes ensure consistent and reliable light transmission in every unit produced, which is essential for product quality, safety, and compliance across industries like telecommunications, data storage, aerospace, medical, automation, robotics, and industrial controls.

• Learn more about Optopipe® light pipes.

• View our full selection of precision-engineered light pipes.

Designing with LED indicators might seem like a small part of your project, but getting it right can make all the difference. Whether you're building a control panel, compact PCB, or rugged industrial device, selecting and integrating the right LED solution is essential for performance, reliability, and compliance.

At Dialight, we support you at every step of your electronics manufacturing journey. From initial concept to final delivery, we provide the tools and resources to simplify your process and help you make the best design decisions.

Application Expertise: Our team can help identify the ideal LED indication solution based on your visibility, size, voltage, and environmental needs.

Product Overview: Explore our full Optoelectronics portfolio of PCB and panel indicators to see what’s possible.

Parametric Search & Selector Guides: Quickly compare options by size, color, mount type, voltage, and more.

Datasheets & Cut Sheets: All the technical specs at your fingertips.

2D & 3D Drawings: Download design files to speed up prototyping.

Free Samples: Request samples to evaluate fit, form, and function.

REACH, RoHS, and Material Declarations: We've got the paperwork covered.

Check Stock: Use our NetComponents integration to instantly see availability across distributor partners.

Competitive, Reliable Solutions: Our pricing reflects the quality and reliability you expect from a trusted brand.

Global Distributor Network: Order from trusted partners, wherever you are.

On-Time Delivery: Get what you need, when you need it.

The right LED indicator can upgrade your design from good to great, and with Dialight, finding that solution is easier than ever. Whether you’re just getting started or finalizing your BOM, we’re here to help every step of the way.

➡️ Explore all our tools and resources: Visit the full LED Design Support page

➡️ Need help choosing? Contact us or request a sample—we’re here for you.

Panel mount indicators are widely used in industrial applications where durability, visibility, and reliability are critical. These indicators serve as vital components in control panels, machinery, and equipment, providing visual signals for operators, technicians, and engineers. In this article, we’ll explore why panel mount indicators are the preferred choice in various industrial settings, and how engineers can optimize their selection and design for maximum performance.

1. Rugged Construction for Harsh Conditions

Industrial applications often subject components to extreme conditions such as high temperatures, vibrations, dust, moisture, and exposure to chemicals. Panel mount indicators are designed to endure these harsh environments, thanks to their robust construction and high ingress protection (IP) ratings. Many of these indicators offer IP66 or higher ratings, making them resistant to water and dust, ensuring longevity in demanding settings like factories, outdoor applications, or marine environments.

In addition to IP ratings, many panel mount indicators are built to meet NEMA 4X standards, which ensure protection against corrosion, windblown dust, rain, and splashing water, making them ideal for outdoor use or corrosive environments such as chemical processing plants or food and beverage facilities. This protection ensures that the indicators remain operational and visible even when exposed to harsh cleaning processes or adverse weather conditions.

For hazardous locations, such as oil and gas, petrochemical, or mining industries, selecting panel mount indicators that comply with Class I, Division 2 (C1D2) standards is crucial. C1D2-rated indicators are engineered to operate safely in areas where flammable gases, vapors, or liquids may be present under abnormal conditions. These indicators provide the durability and safety needed in potentially explosive environments, ensuring reliable operation without posing a risk of ignition.

By choosing indicators with appropriate ratings, engineers can guarantee their products are well-suited for the toughest environments, providing reliability and safety when it matters most.

Built to Withstand the Extremes

Dialight's Rugged LED Panel Mount Indicators:

• IK07 Rated: Impact Resistant

• IP66/67 Rated: Dust-Tight and Waterproof

• NEMA 4X Rated: Corrosion Resistant

• MIL-L-3661B Spec: Military-Grade Durability

Engineered for reliable performance in the harshest industrial environments.

2. Ease of Installation and Maintenance

LED Panel mount indicators are designed for seamless integration into control panels, equipment, and machinery, making installation quick and straightforward. These indicators typically come with standard snap-in or screw-in mounting options, allowing engineers to choose the best fit for their application. The installation process requires minimal tools, reducing the time and effort needed to add or replace indicators, which is critical for maintaining uptime in industrial operations.

Panel mount indicators are available in a wide range of mounting hole sizes, from small openings for compact designs to larger diameters for high-visibility applications. This variety makes it easy for engineers to find the right size for their specific project requirements without the need to redesign the panel layout. Whether integrating into a new system or retrofitting an existing one, the flexibility of mounting options ensures that engineers can meet their space and functionality needs efficiently.

Additionally, many indicators offer multiple connection options to further streamline installation. Engineers can choose from simple terminals, wire leads, or quick-connect connectors depending on the application's wiring needs. This flexibility allows for faster, hassle-free installation and easy replacement or maintenance, reducing downtime and ensuring reliable performance. These varied connection methods accommodate different project specifications, making it easier to integrate panel mount indicators into diverse setups.

By offering a range of mounting sizes and connection options, LED panel mount indicators simplify design choices, providing greater versatility for both new installations and system upgrades while contributing to reduced downtime and lower maintenance costs.

Precision Fit for Every Application

Dialight LED Panel Mount Indicators:

• Over 20 mounting hole diameters

• Range: 0.156" (3.9mm) to 1.18" (30mm)

• Continuously expanding product line

• Unmatched versatility to meet your exact specifications.

3. High Visibility for Immediate Feedback

In industrial environments, quick and clear visual feedback is essential for safety, operational efficiency, and monitoring equipment status. Panel mount indicators are available in a variety of bright LED colors (red, green, amber, blue) to communicate different machine states, warnings, or operating conditions. Many indicators feature wide viewing angles or diffused lenses to ensure visibility from multiple positions and under various lighting conditions.

A crucial consideration in industrial settings, especially those exposed to outdoor lighting or direct sunlight, is daylight visibility. Daylight viewable panel indicators are specifically designed to maintain clarity and brightness even in bright, high-glare environments. These indicators use high-intensity LEDs to ensure they are clearly visible, even when sunlight is directly on the indicator, preventing misreads or missed alerts. This feature is particularly important in applications such as outdoor control panels, transportation systems, or marine environments where reliable visibility is critical at all times of the day.

High-Visibility LED Indicators

Dialight Delivers: Daylight-Viewable Options and High-Intensity Models

Superior visibility in all lighting conditions, ensuring critical signals are never missed.

4. Wide Range of Voltage and Current Options

Industrial systems often run on different voltage levels (AC or DC), so selecting the correct LED panel mount indicator to match the operating voltage is crucial. These indicators are available in a wide range of voltage ratings, typically from 5V to 240V, accommodating a variety of applications, from low-voltage control panels to high-voltage industrial machinery. Engineers can also choose indicators with built-in resistors or current-limiting features, simplifying power management in the system design.

A key innovation in this area is the constant-intensity LED indicator, which maintains consistent brightness despite fluctuations in voltage or temperature. This is achieved through the use of a voltage regulator or current-limiting circuit, ensuring reliable and accurate light output even when the input voltage changes. For applications where precision and readability are critical, such as control panels or emergency systems, constant-intensity indicators offer a dependable solution.

An example of this technology is Dialight’s 556 Series Constant Intensity 1” Panel Mount Indicators, which operate across a wide voltage range of 18-48V DC. These rugged, watertight indicators are available in standard and daylight-viewable versions, providing a versatile and durable option for industrial environments. By offering constant brightness, they enhance both safety and performance, ensuring accurate indication in challenging conditions.

Unmatched LED Diversity

30+ Series | Endless Possibilities

Dialight leads the industry with the most comprehensive range of LED panel mount indicators.

Whatever your application or sector, we've got you illuminated!

5. Application-Specific Customization

While many panel mount indicators come in standard sizes and colors, manufacturers often offer customization options to meet the specific needs of a project. Engineers can select different lens styles, such as domed, flat, or recessed, depending on the required visibility and protection. For instance, in industries like oil and gas or chemical processing, selecting explosion-proof indicators with additional protective features is often necessary for safety.

Unlock Your Perfect Look!

Effortlessly discover your ideal indicator with our smart search filters.

Find the perfect color and lens style in just a few clicks!

6. Enhanced Durability with Vibration and Shock Resistance

Industrial settings often expose components to mechanical stress, such as vibrations from machinery or shocks from equipment movement. Panel mount indicators designed for industrial use are built to withstand such stresses without compromising performance. Their sturdy housing materials, often made from metal or high-grade plastic, ensure that the indicators remain securely in place and function reliably over time.

7. Compliance with Industry Standards

Safety and performance standards are critical in industries such as automotive, aerospace, and heavy machinery. Many panel mount indicators meet or exceed industry certifications like UL, CE, and RoHS, ensuring that they comply with regulatory requirements for safety, electromagnetic compatibility, and environmental impact. Engineers can rely on these certifications to select components that align with their project’s standards.

Certified for Quality and Compliance

Dialight LED Panel Mount Indicators:

• UL Certified: Meets rigorous safety standards

• RoHS Compliant: Environmentally responsible design

Ensuring reliability, safety, and sustainability for your critical applications.

1. Transportation

In public transportation applications, panel mount indicators are used for dashboard signals, passenger safety signals, control systems, status alerts, emergency signals, and EV charging stations.

2. Aerospace

Aerospace equipment, both ground-based and onboard aircraft, relies heavily on clear visual indicators for system status, engine diagnostics, and emergency alerts. The ability of panel mount indicators to perform in high-altitude, low-pressure, and high-vibration environments makes them ideal for this industry.

3. Heavy Equipment and Industrial Machinery

In industries like construction, mining, and manufacturing, heavy equipment operators depend on panel mount indicators to monitor the status of machines such as drills, cranes, and conveyors. These indicators provide real-time updates on system functions, ensuring operational safety and efficiency.

4. Marine and Oil & Gas

Panel mount indicators are essential in marine applications and the oil and gas industry, where they are exposed to corrosive environments, extreme temperatures, and potential impacts. Their rugged design, combined with high visibility, ensures they can signal critical information reliably, even in challenging conditions.

Panel mount indicators are indispensable components in industrial applications due to their durability, ease of installation, and ability to provide critical feedback in real-time. By selecting the right panel mount indicator, engineers can enhance the performance and reliability of industrial equipment, ensuring smooth operations and safety. Whether it’s for a rugged outdoor environment, a high-vibration manufacturing facility, or a specialized application like aerospace or oil and gas, panel mount indicators are Always On When It Counts.

Dialight is ready to assist in selecting the ideal LED panel mount indicator to meet your specific performance requirements, application demands, and budget constraints. With a broad range of solutions and expert support, Dialight ensures you have the right indicator for every project.

Contact Us Today

The Role of Power Derating and Environmental Management

To enhance the longevity of LED indicators, it's essential to strike a balance between operational techniques and environmental management. Power derating, which involves operating LEDs below their maximum capacity, plays a pivotal role in extending their lifespan by minimizing component stress. Additionally, addressing environmental factors is crucial for maintaining the reliability of LED indicators over time.

Effective Strategies to Extend LED Indicator Life:

1. Power Derating:

• Current Derating: Operating LED indicators at currents lower than their maximum rating helps control the junction temperature—the critical temperature within the LED chip. Lowering the current reduces thermal load, which in turn enhances lifespan and ensures consistent performance.

Graph showing the relationship between current, junction temperature, and lifespan of a light emitting diode.

Thermal Derating in LEDs: This heat map demonstrates the temperature distribution across an LED and its heat sink. The graph on the left represents the thermal load at maximum current, showing higher temperatures at the junction. The graph on the right illustrates the effects of derating, where operating the LED at a lower current reduces the thermal load, leading to extended lifespan and more reliable performance.

• Voltage Derating: Using a voltage below the maximum rated value prevents the overdriving of the LED indicator, thereby reducing heat generation and the risk of electrical overstress. This practice is particularly beneficial under fluctuating voltage conditions to maintain the LED's operational integrity.

Practical Example: 625 Series LED Panel Mount Indicator, 16MM RGB 3VDC

For instance, our 625-1121-307F panel mount indicator has a maximum current rating of 20 mA. Operating the component at 15 mA reduces heat generation, which decreases thermal stress and extends its lifespan. Additionally, ensuring that the LED indicator operates within its specified voltage range and under controlled environmental conditions can further enhance durability.

2. Thermal Management:

Effective thermal management is crucial for sustaining performance levels of LED indicators. Implementing adequate heat dissipation methods, such as proper heat sinking or other thermal management techniques, ensures that the junction temperature remains within safe limits. This not only maintains the optical performance but also prolongs the operational life of the LED.

3. Environmental Considerations: Factors like ambient temperature, humidity, and chemical exposure can significantly affect the longevity of LED indicators. Operating LEDs beyond their rated environmental specifications can cause premature failures. It is vital to consider these elements when designing LED systems for different applications.

Derating Curves and Environmental Adaptation: Derating curves, often included in product datasheets, provide guidelines on adjusting operating conditions based on ambient temperatures. For example, an LED might be safely operated at 20 mA at temperatures up to 25°C, but at 75°C, the current should be reduced to 10 mA to mitigate excessive thermal stress. Adapting to environmental conditions ensures reliable operation of the LED throughout its intended lifespan.

Understanding Derating Curves: As ambient temperatures rise, adjusting the operating current of an LED is crucial to prevent thermal stress.

By implementing power derating and considering environmental factors, manufacturers and designers can significantly improve the longevity of LED indicators in their systems. These practices ensure that LEDs operate cooler, last longer, and perform reliably under various conditions, thereby minimizing the risk of premature failures and optimizing investment returns.

Choosing the right LED indicator is crucial for ensuring long-term reliability in your applications. At Dialight, we specialize in offering durable, high-performance indicators designed to meet your specific needs. Let us help you find the ideal solution to maximize both performance and lifespan.

Which type is best suited for your application?

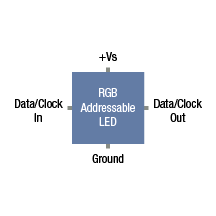

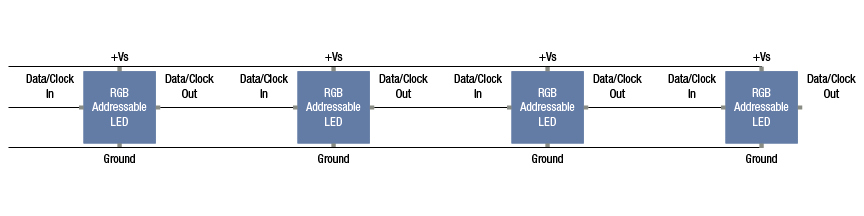

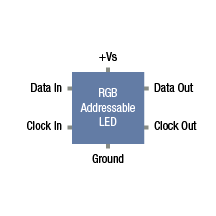

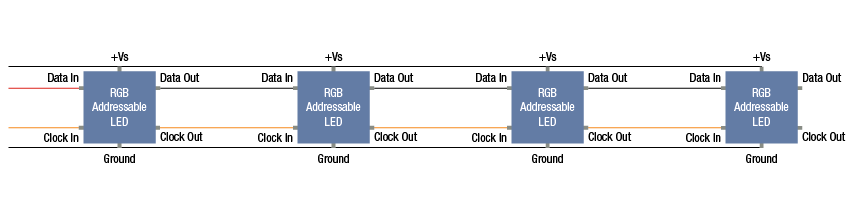

If you're looking for high-quality, addressable RGB LEDs, you must first decide between single-wire and dual-wire options. Both of these options come with unique features that make them desirable in different applications. Here’s a brief comparison between the two types of addressable RGB LEDs.

Single-Wire Addressable RGB LEDs

Single-wire addressable RGB LEDs require only one data wire to control the color and brightness of each LED in the array. They come with an integrated microcontroller that interprets the data sent through the single data wire. These LEDs offer a simpler configuration with fewer wires, making them suitable for applications where simplicity and ease of use are essential.

Other features of Single-Wire Addressable RGB LEDs:

• Slower data transfer rate (typically 30μs to transfer data from one LED to the next)

• Maximum number of LEDs in the array is limited (typically around 1000 LEDs) before noticeable delay.

Dual-Wire Addressable RGB LEDs

On the other hand, Dual-Wire Addressable RGB LEDs use two separate wires for data and clock signals to regulate color and brightness. These LEDs come with a built-in shift register for more precise control and synchronization. They are capable of faster data transfer rates (typically 1.9μs to transfer data from one LED to the next) and can support longer serial connections and larger arrays (up to around 15,000 LEDs) before noticeable delay.

Other features of Dual-Wire Addressable RGB LEDs:

• More advanced control capabilities and higher data transfer rates.

• Require two control wires instead of one, slightly more complex wiring.

To summarize, single-wire addressable LEDs are simpler and suitable for smaller arrays, whereas dual-wire addressable LEDs offer faster data transfer rates and the ability to support larger arrays with more advanced control capabilities, at the cost of slightly more complex wiring.

Make the right choice for your indication needs and select the best addressable LEDs for you. Let us help you decide which option is the best for your application, Contact Us today!