ProblemSolution - Minimizing Mixed Technology on PCBs

PROBLEM: Minimizing Mixed Technology On Printed Circuit Boards

The goal of any circuit board assembly process is to be efficient. There are several guidelines for PCB designers to follow to make the assembly process as smooth, fast, and efficient as possible.

One of these guidelines focuses on component selection. It states that PCB designers should try to select as many surface-mount components (SMT) as possible in order to minimize or eliminate mixed technology boards.

SMT components tend to have lower costs, require less maintenance, take up less board space, and are easier to install when compared to their through-hole (THT) counterparts.

Only if there is no SMT component equivalent or the nature of the application requires it, are through-hole components to be considered.

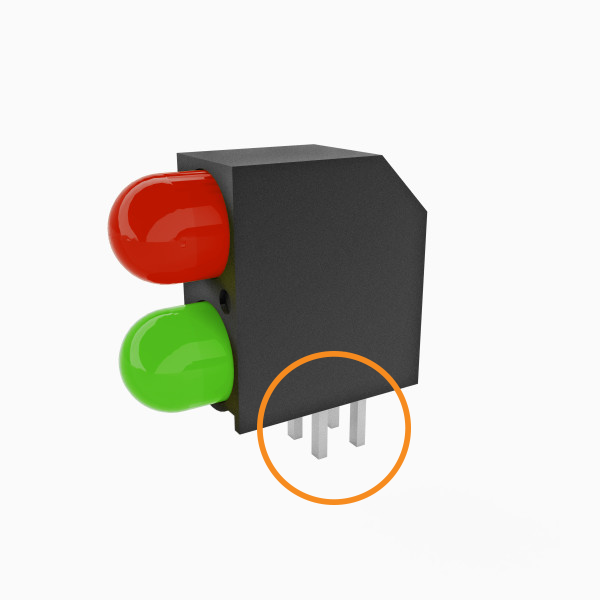

This presents a problem when a circuit board design requires a right-angle, multilevel LED indicator. The typical single- or multi-level, right-angle LED circuit board indicator relies on through-hole technology (THT) and requires wave-, selective, or hand soldering.

Typical THT muliti-level, right angle LED Indicator

However, there are now LED indicators available to the design engineer to solve this problem.

SOLUTION: Multilevel, Right-Angle SMD LED Indicators

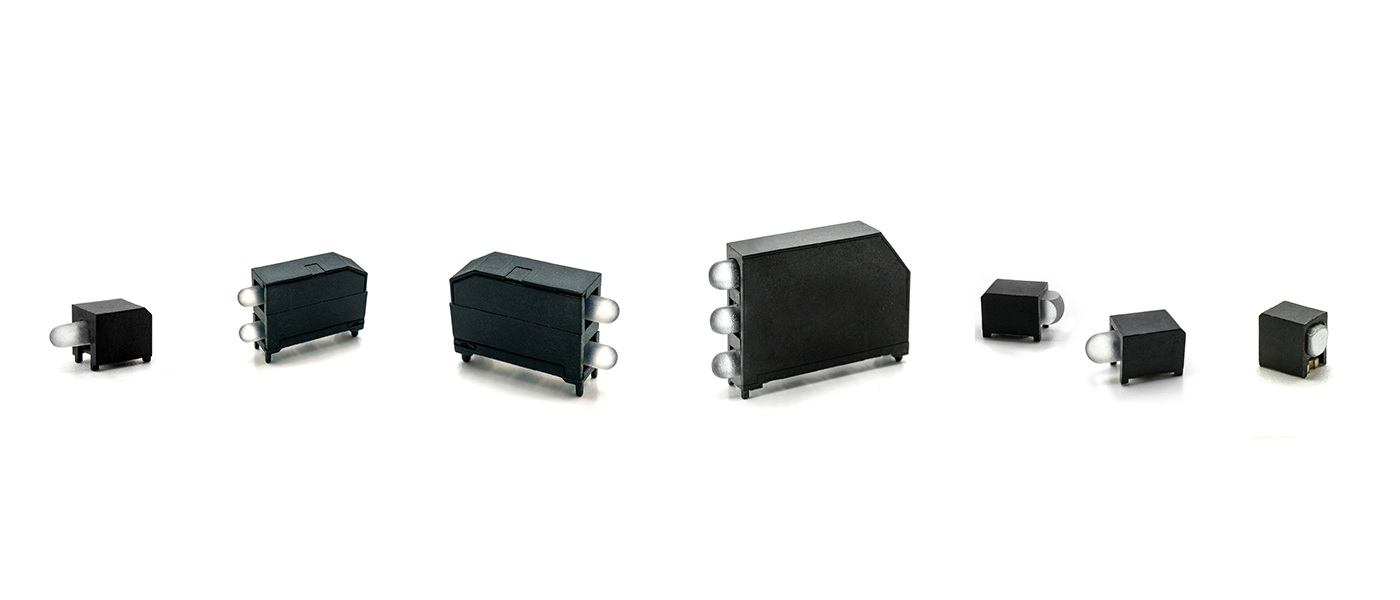

PRISM® SMD LED indicators are specifically designed to reduce mixed technology on PCBs.

These indicators combine the benefits and aesthetics of surface-mount LEDs and shielded light pipes. They are the industry’s only SMD indicator series designed to survive 260°C peak reflow temperature and provide the visual appeal of a diffused lens for enhanced viewing.

PRISM® SMDs are tape and reel packaged and are pick and place compatible.

Ideal for limited-space applications and board-edge mounting, the PRISM® Series is available in a variety of package sizes including single-level, bi-level, and tri-level configurations and in 1.6mm, 2mm, and 3mm lens sizes.